Not All Pallets Are Created Equal!

We sell a lot of different pallets at One Way Solutions- almost 250 different models.

Any when you consider plastic pallet size options, load capacities, industry-specific features, and specific applications, it’s only fitting that we carry an option to suit all circumstances…

because we are pallet experts!

Despite all the variations across our pallet catalog, there is one key specification that allows us easily compare pallet prices versus performance: strength vs weight.

Pallet Strength To Weight Ratio

More material means more weight; as you add more material to a pallet, the cost increases. The best pallet will offer the greatest performance at a minimum weight.

Our latest pallet optimizes this key metric to offer exceptional value to warehouses needing a light/medium duty nestable pallet. Its technical design advancements delivery the brute strength required to satisfy many desired uses.

The NM7 is specifically designed to minimize pallet tare weight without sacrificing strength and durability. This beast of a pallet has a 2,700 lb dynamic capacity. This being said, the NM7 is a heavy weight type of pallet with light weight pricing.

Introducing #PP-O-40-NM7

The design of this pallet makes it a champion performer, minimizing expenses through two main design efficiency goals:

- Structural Economy

- Efficient Production

Structural Economy

The NM7’s design is a complete study in structural economy that optimizes the placement of plastic material, eliminating unnecessary plastic waste through superior design by channeling all plastic materials into the supportive structures of the plastic pallet.

Lean and mean, the NM7 achieves more capacity with less weight, achieving a higher capacity with minimal material cost.

Production Features

Efficient Production

Injection molding machines used to produce plastic pallets are huge machines that require consume massive amounts of power. Less material lowers the NM7s cycle time, driving down the price of the plastic pallet by maximizing the rate of production, lowering part cycle times, and reducing energy costs.

High Pressure Molding

This pallet is truly a work of art- high pressure molding gives it life.

Design Sophistication

The NM7’s high-pressure injection molds allow a complex geometry and with detailed features.

Precise Strength Regulation

Our specialized high-pressure molds allow targeted strength variation. The NM7 has targeted reinforcement in different areas with more or less plastic to help the overall strength of the pallet.

Automated Production Benefits

A majority of this process is run by machines which one individual can observe and control. This mechanical automation reduces manufacturing costs.

With these lowered costs, savings are passed down to the customer for a lower rate while offering superior quality.

Recycled Mold Scraps

Mold Scraps, produced during pallet manufacturing, are reused e reused for the next pallet molding. This process creates minimal waste without impacting the quality of this excellent product.

Maximized Pallet Uniformity & Accuracy

Some pallets have longer production cycle times in production. To boost output, pallet manufactures may try to remove a pallet from the press before it has sufficiently cooled. Removing hot plastic pallets from their mold prematurely causes shrinkage and warping.

When excess material is removed from a pallet design and minimized, faster cooling times result. Simple put, the less plastic used in pallet, the faster it cools!

Unlike other pallets that have longer cycles times, NM7 pallets cool quickly before being removed from the mold, resulting pallets that are:

- True 40″ x 48″pallets

- Remarkably flat

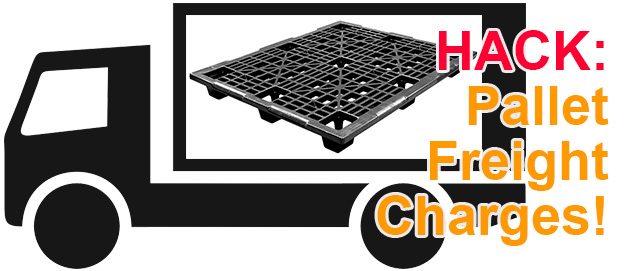

Made In The USA – Shipped From An Ideal Shipping Origin

The NM7 pallet is manufactured and shipped from Michigan. It’s centralized US location is an ideal distribution point to minimize shipping expenses to all areas of United States.

NM7 Pallet Design Benefits

Optimized Pallet Legs

If you take a look at the design you will notice a precise cutouts located in each of the nine pallet legs. These voids reduce pallet weight and cost to our customers. Costs are further reduced when shipping the pallets to our customers, allowing us deliver more pallet performance at lowering shipping rates!

Tapered Pallet Edges

The NM7’s tapered edges assist the fork-tine entry along with splitting a nesting rack, allowing pallet handlers to quickly easily move pallets to their designed location without sweating the details.

Reinforced Pallet Perimeter

The perimeter of the NM7 is reinforced with extra ribs to increasing impact-resistance for a safer, more durable product.

4 Way Entry

The NM7 design enables it to have a 4-way entry compatible with nearly all forklifts and hand trucks.

Open Deck Pallet Design

The NM7’s open deck allows for easy handling, easy cleaning, and further reduces material costs and unnecessary tare weight.

Superior Nesting Ratio

A superior nesting ratio allows for 2100 pallets to fit in a 53′ truck, significantly reducing the per pallet shipping costs.

Material Choice – Recycled High Density Polyethylene

The NM7 pallet is made from Recycled High Density Polyethylene (HDPE). This material has many vital features that makes the NM7 such an efficient pallet of choice. This material is lightweight, yet strong and resilient.

This strength is crucial to the lifespan of heavy shipping goods along with the pallet itself. HDPE has impact resistant properties that makes using this pallet the right choice if safety is in mind.

Some other key characteristics this material consists of is a long lasting product life, while being weather and mold resistant. HDPE frequently replaces heavier materials, partially in light of the fact that our society and many organizations are seeking after sustainable alternatives, for example, decreasing the amount of material utilized in shipping and products. This material being “lightweight while strong” can convert into less impact on the earth and cost.

The higher the density of the polyethylene material utilized the stronger, more rigid and more heat resistant the plastic is. The higher density models indicate better properties in strength, chemical and heat resistance, surface hardness and abrasion resistance.

Ventilated Deck * Chemical Resistant:

Traditional pallets may not be reasonable for specific material handling with operations involving the transportation or storage of specific types of chemicals. The NM7 pallet is a uniquely composed plastic makeup that is impervious to chemicals and toxic materials. Having a plastic ventilated pallet improves moisture resistance, safe handling, and airflow. Plastic does not absorb moisture so it will keep products safe and protected from intruding organisms. With the ventilation an individual is able to move and use this pallet with a high level of safety.

Meets GMA Industry Standards

Ideal Pallet Uses

Ideal uses for the NM7 include:

- One way exports

- Light-medium duty reusable applications

- WIP

- Inventory Storage

- Point Of Purchase Display, and distribution applications.

How Do You Like It?

Please let us know what you think about our NM7 plastic pallet- we value your option and pallet expertise!

Please leave your comments below and contact us for assistance on finding the perfect plastic pallet for the right price.

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.