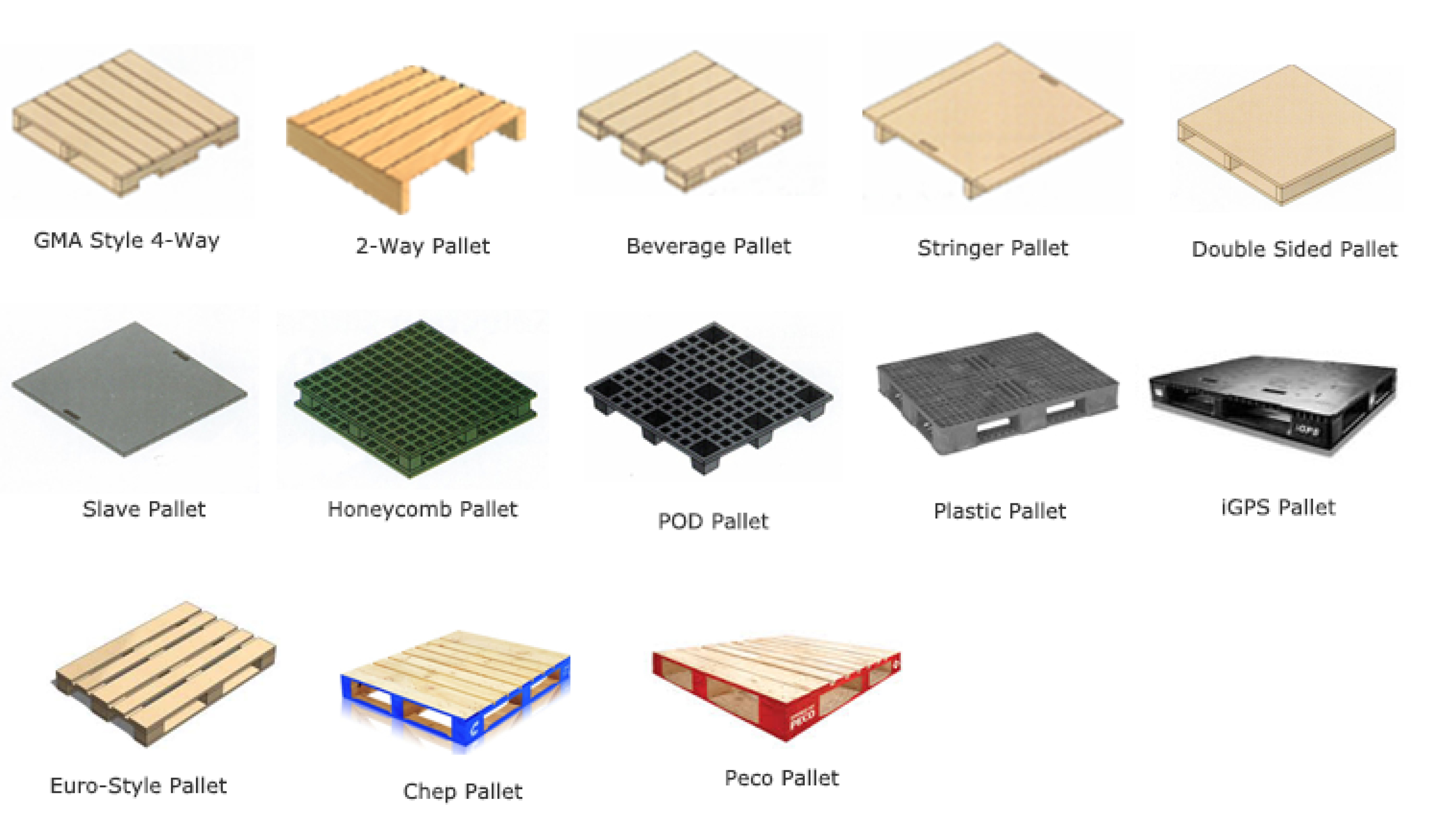

A Euro pallet, also known as a EUR pallet, is a standardized wooden or plastic pallet commonly used in Europe for transporting goods. It is one of the most widely used pallet types globally and conforms to the specifications set by the European Pallet Association (EPAL). 32 x 48/EUR pallets are a common size of pallet used in the EU for transporting and storing goods. The size was originally used to optimize loading of rail cars in the 1960s. These pallets are designed to fit within the standard dimensions of shipping containers and trucks, making them convenient for transporting goods by sea, land, or air.

Key characteristics of a Euro pallet:

- Dimensions: The standard Euro pallet measures 800 millimeters (mm) in width and 1,200 mm in length. This size is often referred to as 800×1200. While not an exact conversion, they are commonly referred to as 32” x 48” in the US

- Construction: Euro pallets are typically constructed using wooden boards and blocks or molded from plastic. The wood version consists of top and bottom deck boards, which are parallel, and multiple middle boards for added support. The corners are reinforced with blocks. Plastic versions have much more variability depending on the design of the mold.

- Entry Points: They have four-way entry points, meaning they can be accessed by forklifts or pallet jacks from any side. Special pallet jacks may be needed to access the 32 inch side, especially in the US.

- Load Capacity: The load capacity of a Euro pallet depends on factors such as the quality of the wood and construction, but a standard pallet can generally support around 1,500 kilograms. Plastic versions capacities vary widely depending on intended pallet use, type of resin, design, or use of rigid support beams such as fiberglass or steel rods.

- EPAL Certification: Genuine Euro pallets carry the EPAL logo, which indicates that they meet the specifications and quality standards set by the European Pallet Association.

- Repairable: One of the advantages of Euro pallets is that they are designed to be repairable. This means damaged components can be replaced, extending the pallet’s lifespan. Most plastic pallet versions are not repairable but can sustain some damage as long as the structural integrity is not compromised.

- ISPM 15 Compliant: If a Euro pallet is intended for international shipping, it must comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15) regulations. This involves heat-treating or fumigating the wood to prevent the spread of pests. Plastic pallets are not subject to ISPM-15 requirements.

- Widespread Usage: Euro pallets are widely used in various industries, including logistics, warehousing, and manufacturing, due to their standardization and compatibility with different types of handling equipment.

- Recyclable: They are made from natural wood, which is a renewable resource. Additionally, they can be recycled or repurposed once they reach the end of their operational life. Plastic versions are recyclable as well while earning more dollars per pound of recycled material than wood.

It’s worth noting that while Euro pallets are a standard in Europe, there are other types of pallets used around the world, each with its own set of specifications and standards. These include pallets like the North American pallet (48×40 inches) and others used in different regions.

The 32 x 48 stackable pallets available at One Way Solutions are environment-friendly and made from recyclable plastic.

As they are durable and reusable, 32 x 48 pallet size tools are resistant up to 120 degrees Fahrenheit and can withstand general outdoor damages from fungi and insects.For example, the 32 x 48 stackable pallets available at One Way Solutions are environment-friendly and made from recyclable plastic.

The 32 x 48 stackable pallets available at One Way Solutions are environment-friendly and made from recyclable plastic.

As they are durable and reusable, 32 x 48 pallet size tools are resistant up to 120 degrees Fahrenheit and can withstand general outdoor damages from fungi and insects.For example, the 32 x 48 stackable pallets available at One Way Solutions are environment-friendly and made from recyclable plastic.

nd can withstand general outdoor damages from fungi and insects.

For example, the 32 x 48 stackable pallets available at One Way Solutions are environment-friendly and made from recyclable plastic.

Design and Manufacturing of 32 x 48 Plastic Pallets

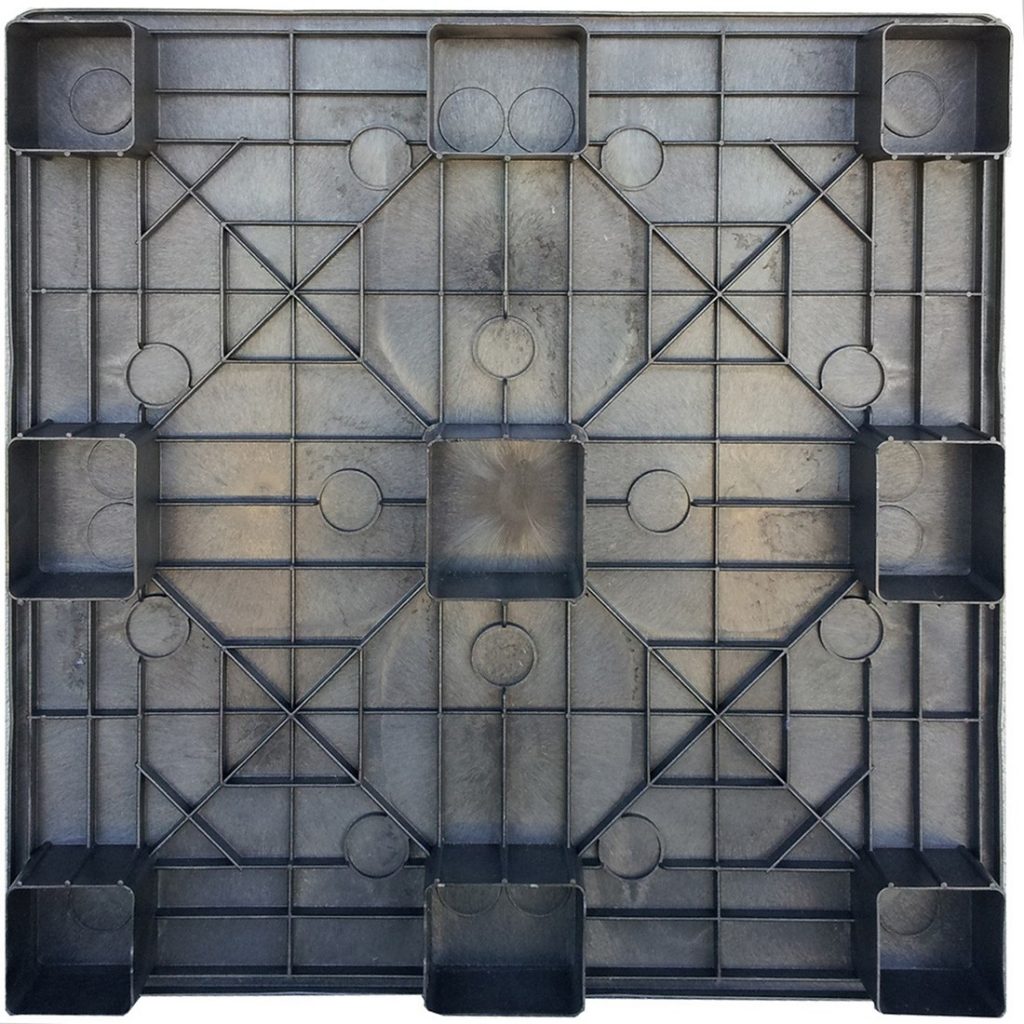

32 x 48 plastic pallets are typically injection molded with high-density polyethylene that contains sturdy impact properties and is highly recommended for storage applications, one-way export use, and returnable syst

It sports a 4-way entry that integrates seamlessly with the majority of hand trucks and fork trucks. Combined with the open deck design is a super nesting ration that allows a total number of 1872 pallets to fit in a 53′ van. This is excellent news for companies and retailers due to the massive reduction in per pallet shipping costs.

Unique Features of 32 x 48 Pallet Size

- Chemical Resistant

- Ventilated Deck

- Anti-Skid Surface

- Sturdy One-Piece Construction

- High-Density Polyethylene

- Safety Lip

Benefits of 32 x 48 Plastic Pallet Size

The 32 x 48 Pallet belongs to a family of thermoformed pallets that are nestable and rackable, depending on your preference. The nestable pallets are used to store, move, and distribute product loads in distribution centers, warehouses, and wholesale supply chains.

Reusable pallets protect both raw materials and finished goods until the product is delivered to its destination. Apart from transportation purposes, 32 x 48 pallets nest for a profitable return. The dimensional consistency of this plastic pallet size ensures seamless integration with different types of high-speed automation, including material handling equipment.

One of the most significant advantages of nestable pallets is the lack of splinters, nails, or broken boards, which could cause injury to employees.

Nestable 32 x 48 Plastic Pallets

The nestable 32 x 48 plastic pallet is thermoformed from dual .250 gauge sheets containing high-density polyethylene that ensures economical toughness. As a made-to-order product, it can be made to accept fork truck entry and four-way pallet jack.

It’s lightweight nature, and ease of handling make it an efficient alternative to wood skids. These properties also make it perfect for end-of-aisle use in retail centers. The nestable 32 x 48 available on Start Studio are fully customizable with ID plates, color striping, and molded-in logos.

Pallets of this exact size also have the ability to carry loads of 3,000 lbs dynamic and 15,000 lbs static.

Rackable and Stackable 32 x 48 Plastic Pallets

Rackable 32 x 48 plastic pallets feature heavy-duty modern plastic materials that are arranged in traditional pallet design. They are perfect for point of sale display, colder loop pallet capture, rough service application, and much more.

The main features of this rackable and stackable plastic pallet size – like the one above – are the solid-deck design and the safety, cleanliness, and durability of synthetic resin with the trusted legacy design.

Choosing the 32 x 48 Plastic Pallet

The 32 x 48 pallet size is popular in the EU and companies exporting to the EU. They are also retailers that use point-of-display retailing. The versatility in use, strength, and user-friendly nature of this particular pallet size makes it a popular choice.

Are you looking for the perfect pallet size? We hope you have been enlightened on the benefits and properties of this pallet size and what makes it an excellent choice for your transportation, display, and storage needs.

Care to share any comments on this article? We LOVE to hear from our readers, so be sure to drop suggestions on the pallet size you want us to discuss next. Till next time!

Let me know how I can help!

* What’s the greatest challenge you face when choosing a pallet size?

* We’re here to help meet unique challenges in your supply chain!

Need Help Selecting A Pallet?

Our Plastic Pallet Experts are happy to help you find the right plastic Plastic Pallet and send you a quote that includes shipping costs.

Please contact us to find the perfect pallet at the best price.

About Robin Kiefer

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.