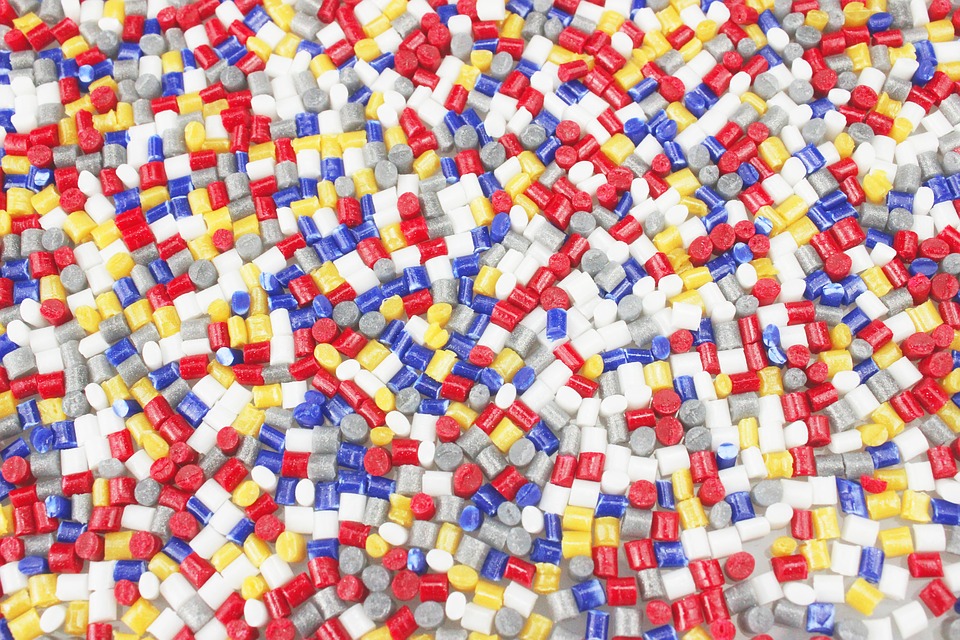

Does NMFC matter for shipping plastic pallets?

When shipping plastic pallets, the right NMFC classification makes all the difference. When one a valued customers reached out with quesions about NMFC (National Motor Freight Classification) codes, we were happy to help.

In this blog post, we’ll delve into the importance of selecting the correct NMFC code for your shipments and shed light on the current status of these codes as of October 2023.

What help did our customer need?

Also: Ways to lower freight costs – saving money on Plastic Pallet shipments?

Specifically, they were puzzled by the absence of NMFC 150390 in their NMFCA account and were contemplating using NMFC 156600 for a plastic pallet order (not to spoil the surprise, but as it turns out, One Way Solutions recommends using a third NMFC 150400 to ship plastic pallets).

Why the Correct NMFC Code Matters

Selecting the right National Motor Freight Classification (NMFC) code is vital for securing the best freight rating for your shipments. These codes are used by carriers and freight brokers to classify various commodities based on factors such as density, stowability, and handling requirements. An accurate NMFC code ensures that your shipment is appropriately categorized, which can significantly impact the shipping costs, transit time, and even the carrier’s willingness to handle your cargo.

NMFC 150390: Is it Still Valid for plastic pallets?

NMFC code 150390, previously used for shipping plastic pallets, has undergone a significant change as of October 2023. NMFC code 150390 is no longer active (and therefore no longer applicable for shipping plastic pallets). This development underscores the importance of staying up-to-date with NMFC code changes, as using an outdated code can lead to costly errors and complications in your shipping process.

Introducing NMFC 150400: The New Standard for Plastic Pallets

As of October 2023, plastic pallets now fall under NMFC 150400, which is classified as “Pallets, Platforms, Skids, or Shipping Racks.” This code is density-based, which means that it takes into account the weight and dimensions of the pallets, providing a more accurate reflection of their characteristics. Density-based NMFC codes are ideal because they help ensure fair and consistent pricing based on the actual space and weight your shipment occupies.

The Advantages of Using Density-Based NMFC Codes

There are several advantages to choosing density-based NMFC codes like NMFC 150400 for your plastic pallet shipments:

- Accurate Pricing: Density-based codes lead to more precise freight rates, helping you avoid overpaying or underestimating shipping costs.

- Fair Treatment: Carriers can assess the space and weight requirements accurately, leading to fair treatment for your shipments and a reduced risk of disputes.

- Streamlined Shipping: Using the right NMFC code reduces the chances of delays or issues in transit, ensuring a smoother shipping process overall.

- Cost Savings: By accurately representing the characteristics of your shipment, you can potentially negotiate better rates with carriers and optimize your shipping budget.

NMFC 150400 vs. NMFC 156600 for Plastic Pallets

While NMFC 150400 is now the recommended classification for plastic pallets, you might wonder about NMFC 156600. NMFC 156600 also covers plastic pallets, but we believe NMFC 150400 is the preferable choice for a few reasons:

- Specific Description: NMFC 150400 explicitly lists pallets in its description, making it a more accurate and transparent choice for plastic pallet shipments.

- Industry Standard: NMFC 150400 aligns with industry practices and provides a standardized approach to classifying plastic pallets.

- Consistency: Choosing the same NMFC code for plastic pallets across your shipments can lead to consistency in rating, reducing the potential for rating disputes and ensuring better control over shipping costs.

In conclusion, selecting the correct NMFC code is essential for achieving the best freight rating and ensuring a smooth shipping process. As of October 2023, plastic pallets are no longer shipped under NMFC 150390; instead, NMFC 150400 is the recommended classification. Density-based NMFC codes like 150400 offer advantages such as accurate pricing, fair treatment, and potential cost savings. When it comes to shipping plastic pallets, choosing the right NMFC code is a vital step in optimizing your logistics and achieving cost-effective and efficient freight transportation. At One Way Solutions, we’re committed to helping our customers make informed shipping decisions, and we’re here to assist you in navigating these changes.

We Hope That Helps!

We hoped you enjoyed learning about choosing NMFC codes for plastic pallets.

We’d love to hear from you – please let us know how you’ve saved money rating freight for plastic pallets.

Need Help finding competitive prices on pallets and plastic pallet shipping?

Our Plastic Pallet Experts are happy to help you find the right plastic pallet Plastic Pallets and can send you a quote that includes shipping costs.

Please contact us to find the perfect pallet at the best price.

About Robin Kiefer

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.