Best Plastic Pallets

What are the best plastic pallets? Some say inexpensive plastic pallets are the best. Some say a pallet’s dimensions, like its size and weight are the most important factors. Pallet capacity is also extremely important to consider.

But what about less obvious pallet specifications, like longevity and durability? Because pallet applications and handling technique vary infinitely by employee, warehouse, and industry, etc, its very difficult to calculate!

So What Makes The Best Pallet?

Ultimately, it’s all in the details.

The features and specifications that are most critical to your material handling success could be all of following factors!

Pick the pallet that satisfies as many of the following characteristics as possible, and you’ll be on your way to pallet nirvana.

Best Plastic Pallets Factors

Pallet Price

Price plays an important part in determining our list of best plastic pallets. The most perfectly designed, beautiful, lightweight pallet that can hold a Sherman Tank doesn’t do much good if it’s not competitively priced.

Alternatively, it wouldn’t make sense to sell our cheapest plastic pallet if it doesn’t match the customer’s application requirements.

But the price is important factor when selecting a plastic pallet – and our online pallet store makes it easy to filter pricing to find the right pallet at the right price.

Pallet Design

The design Very simply, we are looking for the most efficient use of resin material. The majority of a plastic pallets’ price is determined by its weight.

A pallet with a high capacity and low weight will have a good strength to weight ratio. The higher the ratio, the more efficient the design will be.

A good example of a plastic pallet with a high strength to weight ratio is the PP-O-40-NM7.

Pallet Material

Plastic pallets are typically manufactured with HDPE (High Density Polyethylene), PP (polypropylene), or Fiberglass.

Each material has it’s own advantages and disadvantages. Regardless of material type, material quality is important.

The majority of plastic pallets are made with recycled resin which can contain fillers and contaminants.

If you’re unsure about the quality of pallet material, request a report from the material batch test.

Pallet Durability / Impact Resistance

Plastic pallet durability is a function of material, weight, and design.

Pallets molded with HDPE will tend to have better impact resistance than PP.

PP is a stiffer material which has its own advantages when it comes to load capacity.

Though infrequently used due to its higher cost, fiberglass has the best impact resistance.

Pallet Capacity

Pallet weight capacity is the single most important factor to consider when deciding which plastic pallet is right for your company. An overloaded pallet is a deadly disaster waiting to happen and something we take very seriously.

At One Way Solutions, we are very conservative with our published capacity ratings. We never use point of failure as our maximum rating, but rather allow for a margin of safety to mitigate variations in materials, temperature, loading pattern, and handling techniques.

It’s very important to understand that all ratings in the plastic pallet industry assume the pallet is uniformly loaded over the entire pallet surface.

The majority of failures we’ve seen are due to point loading. Point loading is a non-uniform pallet load in which there is variations in the weight per unit of area on the pallet deck.

The best plastic pallets will have low weight to capacity ratio, which is related to design efficiency. A good example of a pallet with a high capacity relative to its weight is the PP-O-40-NL7.

Higher isn’t always better. Paying more money for high capacity pallets for a low capacity application usually doesn’t provide any advantage assuming the pallets are loaded and handled properly.

Pallet Weight

A low weight pallet is typically less expensive and cheaper to ship. However, often times, low weight pallets don’t have the durability or impact resistance that a bulkier pallet will have.

Export plastic pallets are typically light weight because they need to be cheap since they are usually considered a single use pallet. Alternatively, pallets used in a returnable system and need to last for years will have a higher weight.

Pallet Weight To Capacity Ratio

This is a good indicator of how efficient the pallet design is. The goal of any pallet design is to obtain application goals using the least amount of material. There are exceptions when there are added features that are necessary but don’t affect capacity.

For example, solid deck pallets are sometimes required for clean room environments, but the solid deck doesn’t increase the pallets capacity.

We hope that helps!

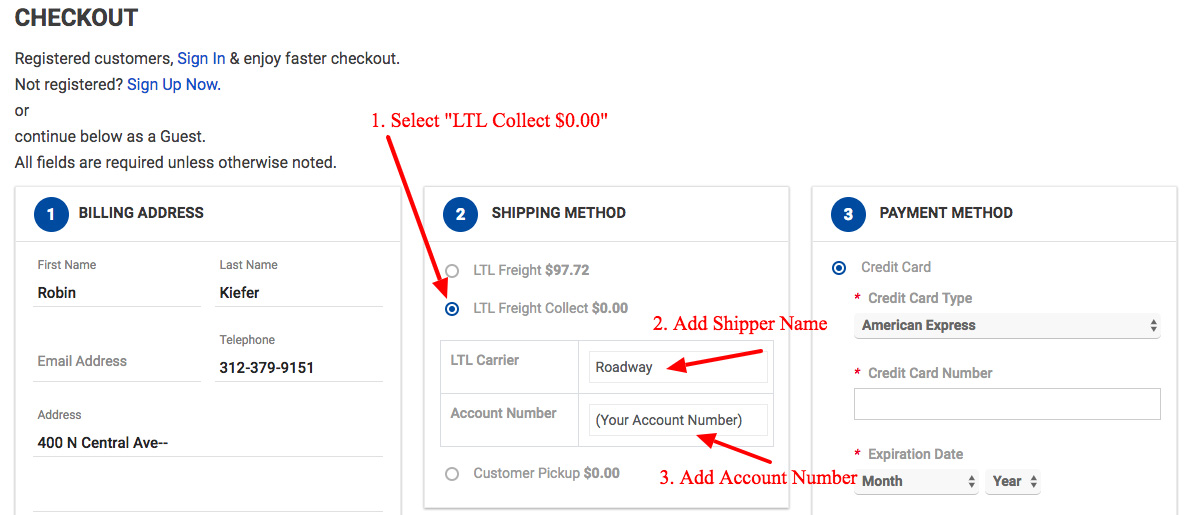

We hoped you enjoyed learning how plastic pallet shipping charges can be reduced.

We’d love to hear from you – please let us know what tricks have helped you save money in the comments below.

Need Help Selecting A Pallet?

Our Plastic Pallet Experts are happy to help you find the right plastic pallet and send you a quote that includes shipping costs. Please contact to find the perfect pallet at the best price.

About Robin Kiefer

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.