What is a Pallet Lip

A pallet lip, also known as a pallet safety rim, is a raised edge on all 4 sides of the pallet that extends above the pallet deck.

Pallet Lip / Safety Lip

The pallet safety lip is found along the edge or perimeter of the four sides of the pallet.

The purpose of the pallet lip is to simplify the material handling flow by offering additional benefits over lipless pallets.

Pallet Safety Rims can be found on nestable pallets, stackable pallets, and rackable pallets.

But why would you need a lip on your pallet?

Benefits Of Pallet Safety Lips

As it turns out, there are many benefits to choosing plastic pallets with safety rims.

Pallet lips can help reduce freight preparation times, conserve packing materials, secure payloads, increase employee safety, and simplify pallet stacking.

Reducing Freight preparation times

Pallet Safety Rims reduce freight loading times by reducing the need and time spent banding and shrink wrapping freight while preparing for shipment.

Need to quickly transfer goods to a different area within your facility? Time consuming shrink wrapping can be drastically reduced because loads are more secure from the moment they hit the pallet!

Conserving Packing Materials

Pallet Safety Rims help conserve the use of packaging materials materials and equipment.

Material handling professionals can be less reliant on shrink-wrap, pallet banding, and the machinery and accessories related to those packaging materials), saving warehouses time money.

Securing Payloads

Pallet Safety lips reduce the likelihood of payload unexpectedly separating from the pallet.

This helps reduce the likelihood of repacking charges imposed by freight carriers and limits the considerable expenses incurred by replacing lost or damaged shipments.

Employee Safety

A more secure payload helps reduce the likelihood of injuries caused by slipping / runaway freight.

Easier Pallet Stacking

Safety Rims help when stacking empty pallets; the pallet lips actually help with the registration of top and bottom of stacked pallets to reduce slipping.

Disadvantages Of Pallet Safety Lips

Pallet lips are generally helpful, but you should carefully consider how you plan to use the pallet.

There are certain material handling applications that make Pallet Lips undesirable. Specifically, instances where goods loaded onto a pallet exceed the footprint of the pallet.

In these cases, where the load on the pallet hangs over the edge of the pallet, pallet safety rims can leave marks on the goods carried by the pallet, which may be undesirable if the finished goods are going to be unpacked and brought to a store or showroom floor for sale in their original packaging (packaged for point of sale).

Pallet Lip Options

All pallet safety rims help secure freight, but not all pallet lips are the same.

Pallet Lip Height

Pallet safety rims are available in different heights and lengths. Generally speaking, safety rims are roughly .2″ to .5″ high (5mm – 13mm) high.

Continuous Or Intermittent Pallet Safety Rims

Intermittent Pallet Lips

Intermittent pallet lips do not cover the entire length of a pallet perimeter. This is a good choice when you do not need entire perimeter coverage, often in cases where you are loading larger and more tightly packed boxes onto the pallet.

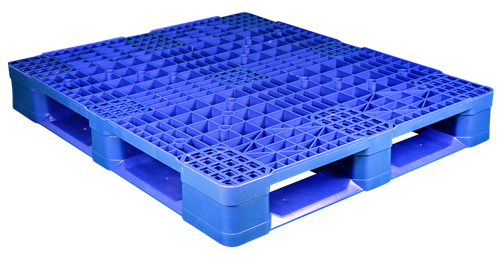

Continuous Pallet Lips

Continuous pallet lips, like the one pictured below, cover the entire length of the pallet sides, and particularly helpful when shipping smaller or more loosely packed pieces on a pallet.

Full Perimeter Pallet Lip

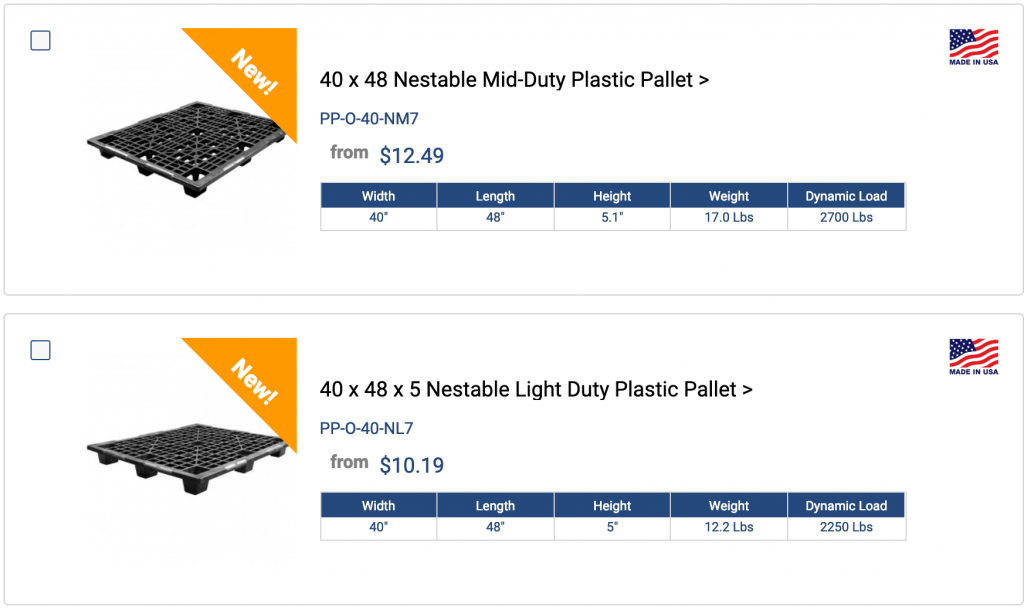

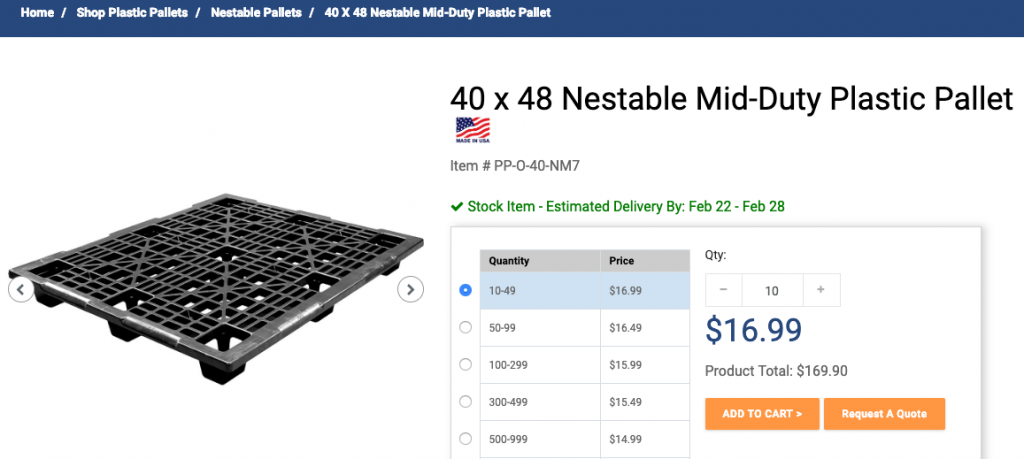

Pallet Safety Lip Pricing

Do pallet safety rims impact pricing? Absolutely!

Pallet lips are formed by plastic that is molded into the pallet body during the manufacturing process for strength. The additional material required to for the lip means more cost, but these costs are nominal and are far outweighed by the benefits offered to material handlers.

Let me know how I can help!

* What’s the greatest challenge you face in your warehouse?

* We’re here to help meet unique challenges in your warehouse!

Share your Comments!

We’d love to hear from you – please let us know what other tricks you’ve used to save on freight – and check our our article on other ways to save money on pallet shipping charges.

Need Help Selecting A Pallet?

Our Plastic Pallet Experts are happy to help you find the right plastic Plastic Pallet and send you a quote that includes shipping costs.

Please contact us to find the perfect pallet at the best price.

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.

Robin Kiefer

Robin Kiefer

February 16, 2020

February 16, 2020