Heat Treated Pallets (HT Pallets)

Today we’re going to talk about heat treated pallets, find out what makes them special and beneficial, and discuss an alternative to heat treated pallets.

Wood Pallets In Action

Pallet Treatments

Some pallets are untreated. These untreated pallets are known as “national pallets”, because they lack ISPM pallet certification and are therefore not used for international trade and foreign travel.

Pallet Treatments – For Safety

Wood pallets are treated to reduce the spread of pests and inhibit the growth of fungi and other organic matter to increase consumer safety and the stability of regional ecosystems.

There are many wood pallet treatment processes for making pallets safe for use:

- Chemical Pallet Treatments

- Fungicide Pallet Treatments

- Pressure Treatments

- Heat Treatments

No Bark!

At the very least, treated pallets must be debarked prior to their treatments. Because bark can harbor pests and their eggs, it has to go!

Heat Treated Pallets

Heat Treated or FT Pallets are subjected to a very specific heat treatment.

The heat treatment kills bugs and their eggs and reduces the wood’s moisture level.

Reduced moisture means that the pallet loses weight during the heating process as well!

HT Pallet Recipe: Bake Wood Core at 56°C (134.6°F) for 30 Minutes

Just what exactly has to happen for a wood pallet meet the heat treating requirements to meet ISPM15 requirements?

The core temperature of any wood pallet greater than 6MM in thickness must be raised to 56°C (Celsius) for no fewer than 30 continues minutes. Reaching the 56°C wood core temperature for half an hour destroys pests, their eggs, and organic plant life that may contaminate the payload or impact other ecosystems adversely.

Wait, what are we here in the US? We’re Fahrenheit.

So 56°C is 134.6°F – which is roughly equivalent of the hottest recorded temperature in the USA:

134°F at Furnace Creek, Death Valley, CA (July 10, 1913)

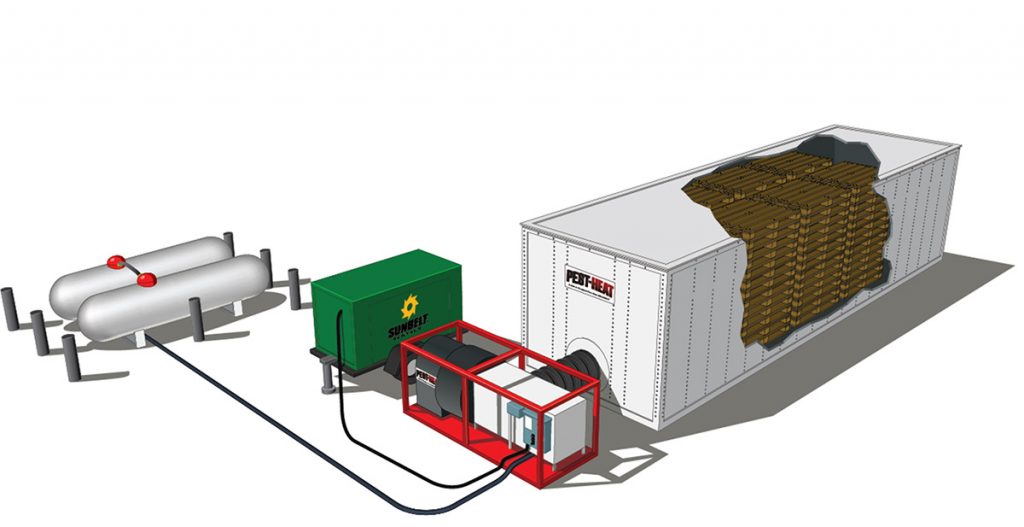

What Does A Pallet Heater Look Like?

Pallet Heater, Pallet Kiln, whatever you call them, they have one essential purpose: to heat the pallets to 56°C and keep it there for 30 minutes.

Here’s one of the little devils now:

Pallet Heater or Kiln

Pallet Heater System Components:

* Fuel Source (natural gas or propane) – The fuel used for heating, sometimes kept in separate tanks

* Power Supply – Powers the heating and air handling devices

* Heating Unit – Creates heat from burned fuel for the heated air used to dry the pallets

* Air Handler – Forces the heated air into the heating chamber

Some pallet heating systems combine the heater and air-handler into an integrated unit, heating the air and forcing it into the heating chamber.

ISPM 15 Stamps – What do they look like?

The IPPC stamps used to indicate that a pallet manufacturer has met ISPM 15 standards looks something like this:

Heat Treated Pallet Stamp (HT Pallet with ISPM15 Stamp)

And as you might have already guessed (or already know) –

HT stands for Heat Treated.

Here’s another example of an ISPM 15 style stamp.

Heat Treated Pallet Stamp (HT Pallet with ISPM15 Stamp)

The Downside To HT Pallets

Well, there aren’t any problems to using HT Pallets specifically; they’re better than using MB Wood Pallets (pallets treated with the now banned MB – methyl bromide).

The problem with MT Pallets is that they are wood pallets and are not the first choice for efficient and cost-effective material handling due to the normal wood pallet disadvantages:

* Added weight of wood causes higher transportation costs

* Lack of uniformity causes interruptions and failure during transport and storage

* Splinters can risk health of all hands in the supply chain, and can cause contamination, exposure to blood borne pathogens, and payload damage.

* High cost of replacement over the long term due to lower service life compared to plastic pallet alternatives.

The Wood Pallet Alternative Is A Plastic Pallet Advantage

Are you ready for a pallet that will last longer, weighs less, performs better, causes less downtime, doesn’t need to be treated, can comply with FDA regulations, and will cost you less to use in the long haul?

Plastic Pallets are the answer – and our pallet experts can help you find the perfect fit to your needs.

Share your Comments!

We’d love to hear from you – please let us know what other tricks you’ve used to save on freight – and check our our article on how FDA Pallets can help food and pharma companies work better!

About Robin Kiefer

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.

Robin Kiefer

Robin Kiefer  May 17, 2019

May 17, 2019