Canned Goods Market

Currently, the canned food market size is estimated at $17 billion. Already impressively sized, this market is forecasted to grow over the next ten years due to:

* the increasing popularity of convenient “ready-to-eat” foods

* general expansion trends within the canned goods distribution infrastructure

In order to meet the demands of this market growing, it’s imperative that the industry optimize its supply chain. If you’re a producer or distributor, using the proper equipment throughout your supply chain will help your transportation become more efficient and increase profitability.

Wood pallets, the traditional tool of choice, may seem like a good fit for this industry on the surface, however, the benefits of plastic can pallets offer a much better fit to the applications of the Can Pallet Industry.

What Is A Can Pallet?

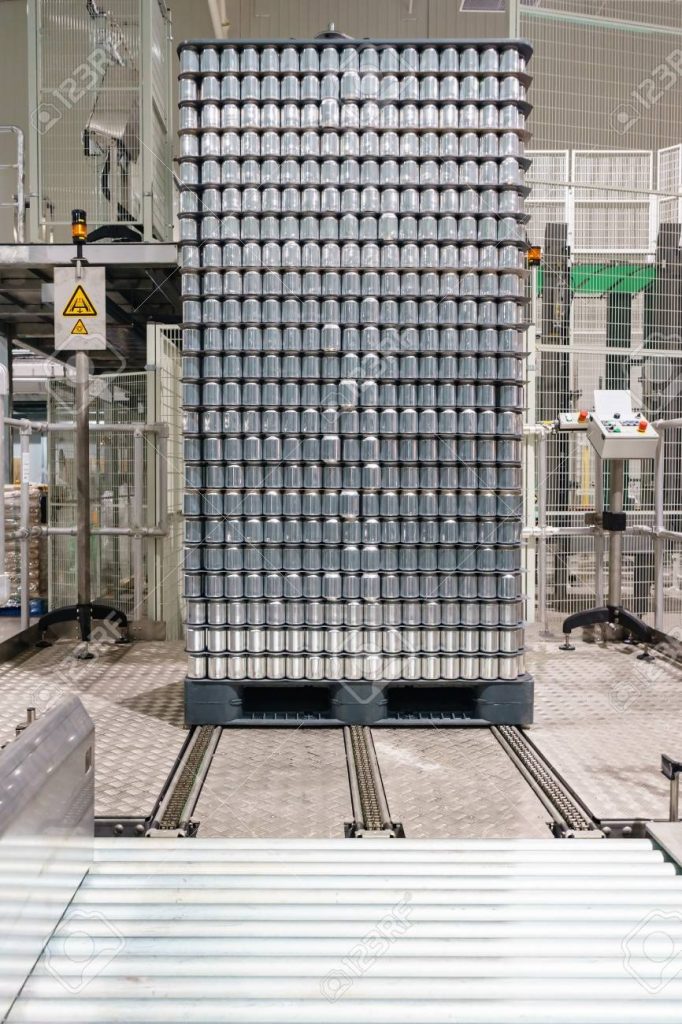

Well, you know what a can is:

* a can of green beans

* a can of tomatoes

* creamed corn anyone?

* It’s Saturday somewhere in our galaxy – how about a can of beer?

Can Pallets hold cans, filled and unfilled – which leads to the two major types of Can Pallets.

Two Types Of Can Pallets

There are two types of can pallets – empty and filled.

Below that, there are even more sub categories – food can pallets and beverage can pallets!

Filled Can Pallets

Filled Can Pallets weigh more and have a greater capacity to carry filled cans that are themselves more heavy because (as you may have guessed) they are filled cans!

Filled cans are usually loaded onto 36″ x 36″ and 37″ x 37″ can pallets.

Empty Can Pallets

Empty Beverage Can Pallets are 44″ x 56″ inches, and use tier sheets (layer pads) between each tier or layer and a top frame so that the can pallets can be strapped tightly together.

Using Wood Can Pallets

Wood Pallet Disadvantages in Canned Good Industry

The shipping process in the canned food industry is crucial and complicated. While there can be many reasons to using wood pallets for material handling and freight, this Canned Goods Industry is not suited for them.

Plastic Pallets are a much safer and efficient solution for shipping canned goods.

Here are some of the main disadvantages of using wood pallets.

Wood Pallets Have Uneven Surfaces

The main problem with wood can pallets is the lack of dimensional consistency, most usually seen in uneven deck surfaces.

Can Pallets have to be perfectly flat because a small imperfection on the bottom layer becomes amplified on the top layer, leading to imbalances and accidents.

Wood Pallets Shed Wood Fibers

Wood fibers falling into cans was a major decision to flip the industry to plastic.

Heavier Loads Can Break Wood Pallets

Canned Goods are heavy shipments, so they require pallets that are not going to break under added stress and weight. While wood pallets are known for handling heavier weights, they also breaks much easier than plastic, resulting in lost money and goods, costly downtime, and increased likelihood of worker injury.

Even though plastic is lighter, it has excellent durability and can offer useful lifespan far greater than wood pallets.

Increased Transportation Cost

Wood pallets can actually increase shipping costs.

Shipping canned goods is already expensive enough. Using heavy pallets to ship those heavy loads adds additional, unneeded cost to your operations, reducing your bottom line profitability.

The durability and lightweight nature of plastic pallets and lightweight can save your company time and money during the stressful shipping process. Reducing costs can allow you to reduce costs and be more competitive in the marketplace.

Product Damage

Wood pallets are more likely to damage your payload.

When pallets break, the product can become compromised, resulting in spills and even spoilage. Wood pallets can develop sharp edges, splinters, and protruding nails that can puncture or tear your product.

On the other hand, plastic pallets do not break as easily and can retain their size and shape despite stressors.

Food Safety and Hygiene

By minimizing damage to the product during transportation, you reduce the chances of contaminating canned food products. With the strict FDA and FSMA requirements for safety and hygiene, you need to be careful about which pallet you choose for this industry.

In order for wood pallets to pass these regulations, they must be fumigated or chemically treated, which can lead to more problems.

You can easily purchase FDA approved plastic pallets, saving you money and making the shipping process easier.

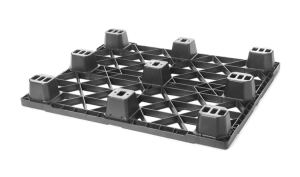

OWS Can Pallets – Perfect For Canned Food

Plastic Pallets are the ideal choice for the canned food industry. Their durability and lightweight nature allow for a very cost efficient and safe supply chain experience.

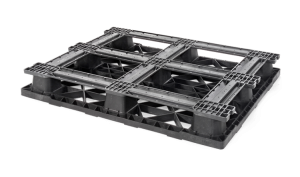

At Oneway-Solutions we offer high quality can pallets for the canned food industry which are designed to efficiently and safely move cans from the manufacturer to the can filler.

Finding The Best Plastic Can Pallet can be a hassle –

we can help!

* What’s the greatest challenge you face as a material handling professional in the canned food industry?

* We’re here to help meet unique challenges in your warehouse!

Share your Comments!

We’d love to hear from you – please let us know what other tricks you’ve used to safely transport other food products from rapidly emergent new product categories.

Need Help Selecting A Pallet?

Our Plastic Pallet Experts are happy to help you find the right plastic Plastic Pallet and send you a quote that includes shipping costs.

Please contact us to find the perfect pallet at the best price.

About Robin Kiefer

Robin Spencer Kiefer connects customers with solutions and products. Robin is the Digital Marketing Manager of One Way Solutions.